Dust smoke treatment system

What is dust treatment system?

The dust treatment system is a equipment for collecting emissions and dirt in the production and air. Based on the principle of centrifugal suction force, creating airflow movement and providing clean air sources instead. At the same time, gathering dust to the container systems to treat dirt, emissions escape to the natural environment, returning to the natural environment and workplaces of clean air, safe for human health.

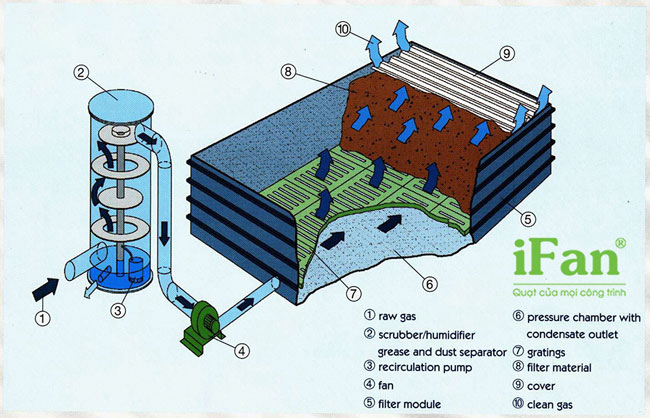

Technology process of industrial dust treatment system

During operation, dust will be collected at the positions generated through suction shooting. The suction shoots directly connected to the dust treatment system, the dust particles in the air are under the effect of the centrifugal exhaust fan will follow the pipeline system through the fabric filter bag.

The dust passing through the fabric filter will be retained by the gap between the fabric and the air will continue to pass. The smaller dust particles adhesion on the surface of the filter fabric due to collision that bearing the gravity and electrostatic attraction. Gradually forming thick dust is called filtering membrane. The filter membrane is capable of sucking very small dust particles. The dust filtration efficiency can reach 99.8%.

Depending on the environmental conditions and the frequency of the factory, the thickness of the dust may be thick or slow. However, when the adhesion is too large, we have to temporarily turn off the dust treatment system and remove the dust on the fabric surface. This is the filtering ability.

The amount of air after passing the fabric layer will move through the device and to the absorption tower. Here the air exposed to activated carbon will eliminate odors and uncomfortable. After leaving the tower of absorbing the gas flow, the centrifugal fan continues to be removed from the chimney to the atmosphere.

Classification of industrial dust treatment system

Classification by the origin of dust.

- Organic dust: agricultural and food waste such as cigarettes, wood dust, agricultural products, livestock products, etc.

- Inorganic dust: metal dust, cement dust, soil, rock.

Classification by dust size.

- Large dust, seed dust.

- Super fine dust.

The smaller the dust, the larger the level of influence due to the ability to wriggle deep into the body, exist for a long time in the air and difficult to handle.

Classification by shape.

- Thin network (thin sheet).

- Fiber form.

- Smoke form.

Depending on the area and characteristics of each factory, we choose different types of industrial dust treatment systems.

Industrial dust treatment methods.

Burning method.

The burning method is the method of using the suction system, then put in the air compressor to burn. Usually this method is used for emissions that cannot be regenerated. With flammable emissions in general and steam emissions paint, CO, industry in particular.

Biological methods.

Biological methods are the method of taking advantage of microorganisms to decompose or consume toxic emissions and emit CO2. This method is suitable for industrial emissions treatment.

There are 3 main methods:

- Processing with Biofilter technology.

-Processing with Bio-Scripber technology.

- Processing with Biocrostor technology contains polymer filter.

Condensation method

In this method, it is divided into 2 categories:

Direct condensation, also known as surface condensation, takes place in the exchange device, with air -proof walls and cooling agents, go in the opposite direction and they are arranged in many layers.

Indirect condensation, also known as mixed condensation, emissions and cooling agents, will contact each other directly, they will condense into liquid, and the gas will be released out, but this method is quite expensive.

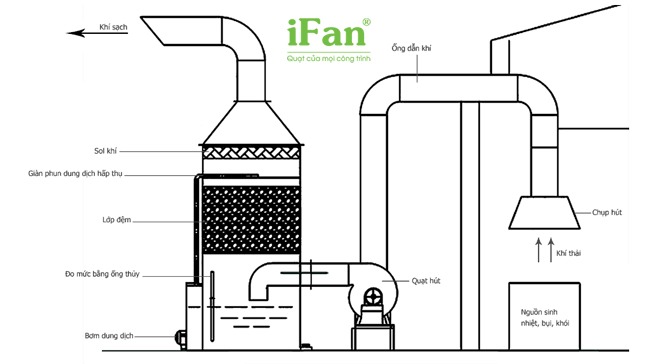

Wet method

Wet method is a method for emissions to be treated in contact with liquid exposure to filter micro dust particles. Finally, the dust is retained and is separated in the form of mud, the effectiveness of this method is up to 90%, more wonderful is the velocity vector of the effect of about 10m/s.

This is a very popular method today that works processing or trust.

Adsorbent method

The adsorbent method is the method of using activated carbon to absorb CO, SO2 emissions, incinerators and laboratory gases.

The principle of this method is to use solid adsorbent to retain gas and slightly toxic, whether these emissions are passed through or not, depending on its importance:

Non -regenerating adsorption: mainly handled in small scale, such as air conditioning.

Absorbing regeneration: Treatment of large -scale waste sources and the amount of emissions with recovery value.

Fixed dust filtration system method

- This system uses filter bags arranged inside a closed chamber, fixed at a position.

- The vacuum cleaner network will be installed in areas where dust generates, focusing on one point.

- Due to the bulky structure, this system is often applied in animal feed factories, cement, bricks, steel, ...

- The advantage of this solution compared to other methods is the ability to filter small dust particles (2-10µm), including moist dust, with high dust filtration efficiency (85-99.5%). Besides, replacing filter bags, filter and system maintenance is also very easy at low cost.

Electrostatic dust filter

- Application in handling flames, potentially explosive risks such as metal dust (aluminum, titanium ...), organic dust (corn scales, bran, epoxy plastic, coal bran ...), ...

- The device has the ability to effectively filter super fine dust particles, smaller than 1µm, even if the dust concentration is high (reaching 50 g/m3).

- Dust filtration efficiency reaches 85 to 99%.

- Stable operation in high temperature environment, up to ~ 5000 degrees C.

- The ability to separate dust effectively, regardless of moisture or dust (liquid or solid).

Use mobile cloth bag vacuum cleaners

- Mobile dust vacuum fans are equipped with modern dust filtration system with dust filter bags placed in an closed chamber, helping to effectively remove fine dust particles, ensuring clean working air is always clean. This device is easy to use, with compact structure and flexible wheels, making it easy to move and clean in every position.

- In particular, with a large dust container capacity of up to 100 liters, a vacuum cleaner can work continuously for a long time without having to replace the dust bag regularly (depending on the capacity and number of dust filter bags).

See the product of ifan's vacuum fans now:

Dust with cyclone

Cyclone vacuum cleaner operates based on the principle of centrifugal force. When the dust -containing air flow into the cyclone device, the centrifugal force will impact the dust particles to touch the device wall. Due to dynamic loss, part of the dust fell to the bottom of the funnel. The remaining dust continued to move the spiral motion down, hit the device wall and finally fell to the bottom. The dust is separated from the airflow and collected through the tightly exhaust valve.

- This is dust treatment system in production facilities with a variety of dust sources such as metal dust, fabric dust, paper dust, food dust, etc.

- Application of centrifugal force to separate dust, via single cyclone device or combine multiple cyclone.

- This cyclone dust filter has the ability to clean the dust -containing air flow at a temperature of up to 400 degrees C.

- Filter efficiency: reached 99.8%

- The ability to handle dust with particle size from 100µm to 10µm.