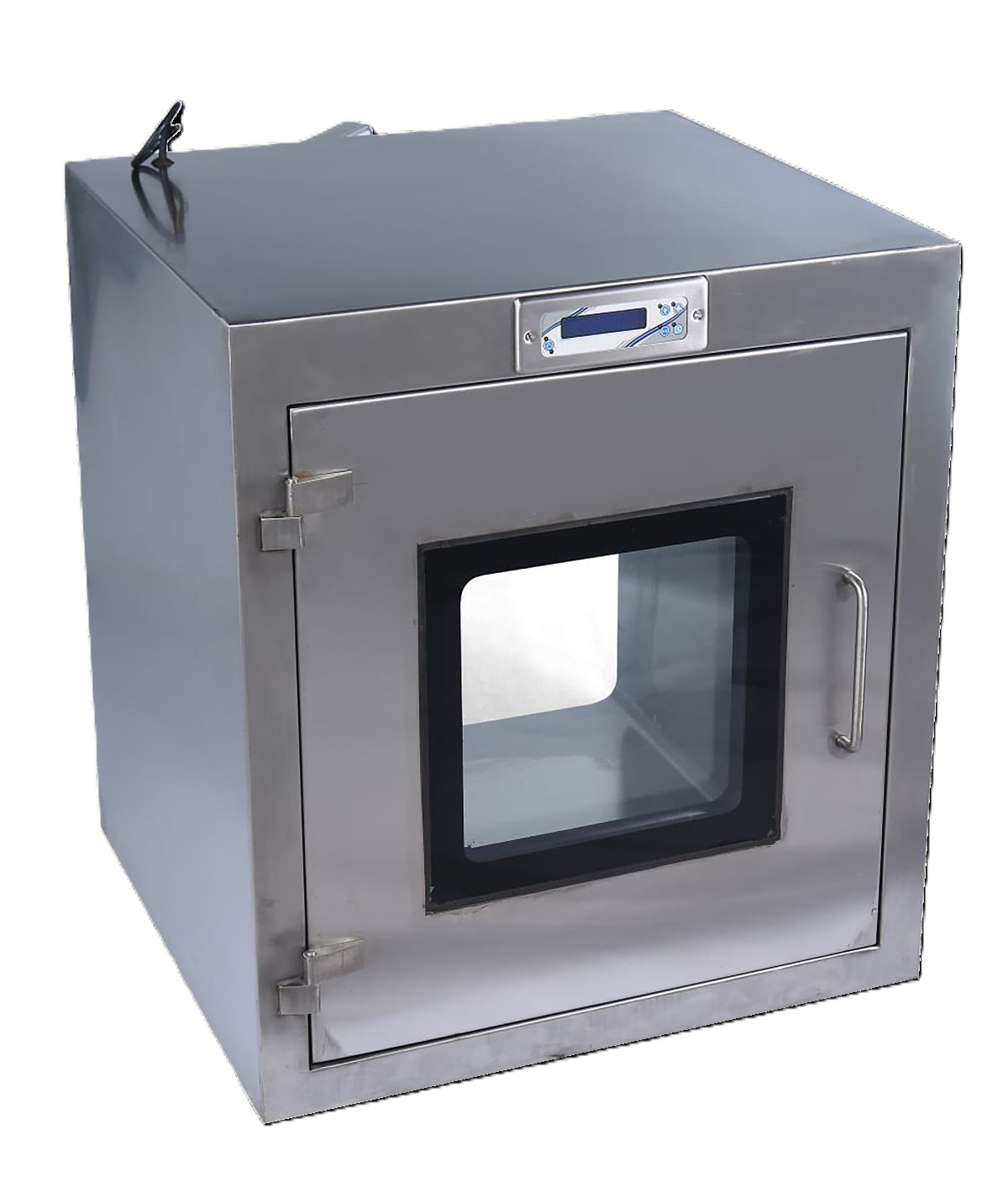

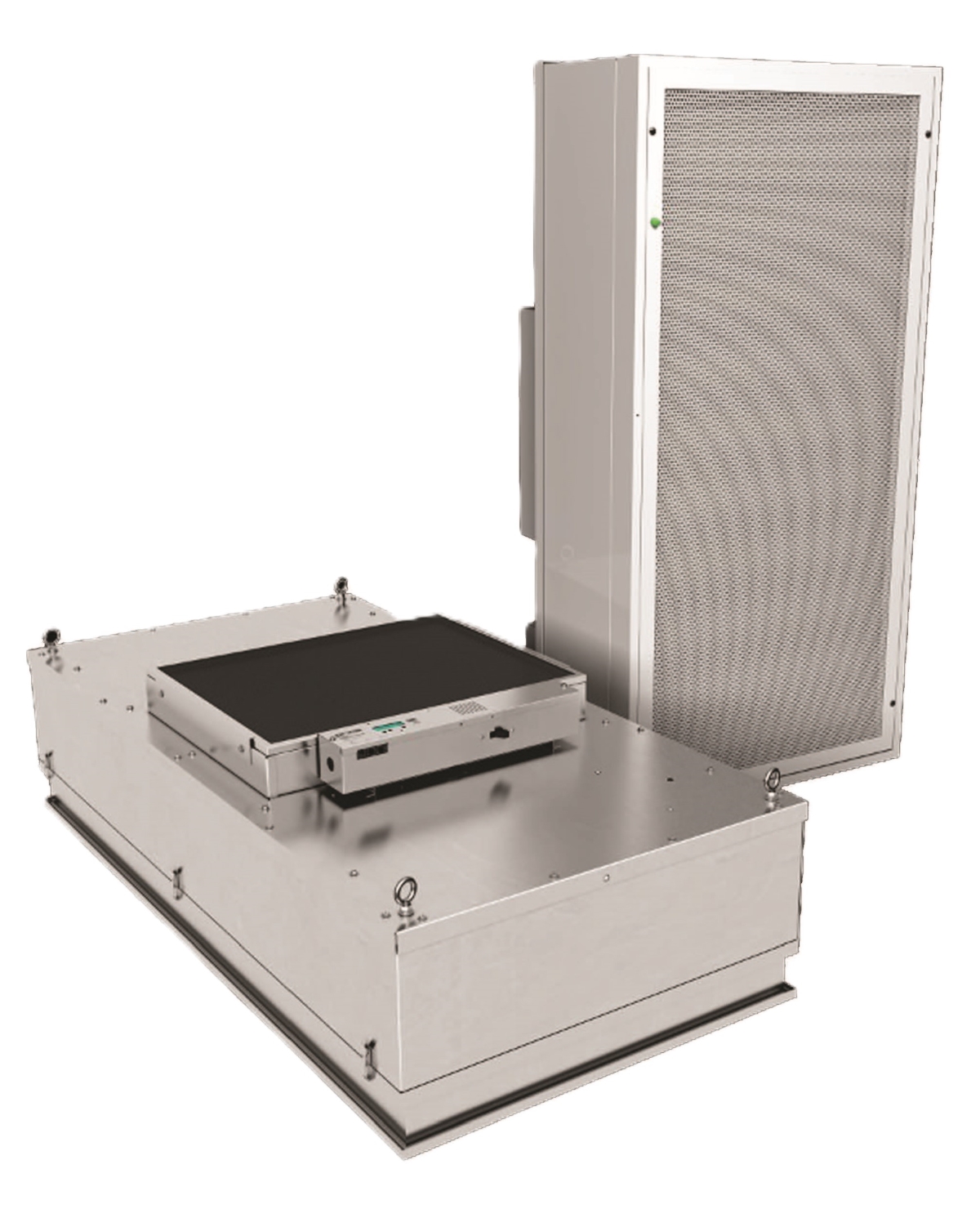

Pass box is a clean room device designed to transfer items between two clean rooms without causing cross -contamination. The basic parameters of the pass box include:

- Size: The size of the pass box is usually customized based on the specific requirements of the user. Common sizes include:

- Outside: 600x600x600 mm, 800x800x800 mm, or larger depending on the requirements.

- Inside: usually smaller than the outer size is about 50-100 mm due to the structure of the wall and door.

- Material : Pass box is usually made from stainless steel material (stainless steel) to ensure durability and easy hygiene. Sometimes, other materials can be used such as Powder-Cater Steel or aluminum.

- Doors: Pass box may have different types of doors such as:

- Mechanical door: Open and close by hand.

- Automatic doors: Open and close by automatic mechanism, usually controlled by button or sensor.

- Intermilized locking system : To ensure safety and prevent cross -contamination, Pass Box usually has an interlock system (Interlock System) to prevent both doors from opening at the same time.

- Air filtration system : Some high -end pass boxes have integrated HEPA air filtration system to ensure the air in the pass box is always clean and does not contain small dust particles.

- Pressure : Pass box can be designed to maintain positive or negative pressure depending on the specific requirements of the production process.

- UV lamp : Some pass boxes are equipped with UV lights to disinfect the inner items before transferring between rooms.

- Dashboard : Pass box may have a control panel displaying information about the door status, pressure, disinfection time, etc.