Industrial emissions treatment system is an indispensable device in manufacturing industries. It helps eliminate toxic gases, returning the cleanest airflow environment. Let's find out the solution solution to bring the highest efficiency.

Where is the emissions born? What types are there?

The most generated emissions perhaps in industrial factories. Most of the production industries generate emissions. Such as:

- In kilns, kilns: Processing factories producing bricks, stones, plastic, ....

- In steel factories, oil and gas exploitation, metallurgy, ..

- In the boilers burning firewood, burning garbage ...

Boiler, boiler

So what kind of emissions are born?

Emission is produced a lot of different substances. However, the most mainly the following types:

- CO2: CO2 is the carbon dioxide or other names as carbon dioxide.

- SO2: This is the main product when burning sulfur.

- NO2: The gas that causes "greenhouse effect" is dangerous to the environment.

- CO: is the main product in the incomplete fire of carbon and carbon containing compounds.

,…..

The unpredictable consequences of industrial emissions

If the emissions, if not treated, will spread out of the environment. From there, causing unpredictable consequences. Affecting human life as well as human health.

Industrial emissions

- Human health: emissions when invading the body will cause many diseases. The most typical is the respiratory diseases.

- Environment: emissions polluting the environment, causing greenhouse effects, changing weather, ...

- Flores: emissions also affect the life as well as the growth of animals.

Solution to install emissions treatment system for businesses

Vietnam's industry and agriculture are growing. As a result, many factories were born. The amount of emissions generated high affects the air environment. Therefore, raising awareness and performing emissions treatment before being released into the environment is very concerned.

Understand that problem, Vinasun - a unit specializing in manufacturing, providing installation of environmental protection air treatment equipment for emissions treatment systems. Help solve the problems of emissions for factories and businesses.

⇒ Vinasun's emissions treatment system

Vinasun's emissions treatment system

The emissions treatment system is a device used to handle polluting components generated during the production operation of factories, enterprises, etc. From there, ensuring that the gas escaped out of the environment will be clean, non -polluted and safe for human health.

The system will include many different components and devices. Often there will be raw dust filter, using the cyclone or//and fabric dust system, and finally, the gas treatment tower is polluted.

Vinasun emissions treatment system can comprehensively handle polluting gases and chemicals, and bring emissions meeting safety standards QCVN 19: 2009/BTNMT.

* Structure of emissions treatment system

The emissions treatment system is designed and produced by Vinasun basically the general structure as follows:

- Tower of exhaust treatment: made from steel SS400 or stainless steel. The tower is designed with long cylindrical shape. It is home to the process of exhaust treatment .

- Industrial exhaust fan: The fan is designed and manufactured by Vinasun, which is adjusted to maximum, so it runs high performance stability. The fan used is an indirect centrifugal line made from steel or stainless steel.

Emissions treatment tower

- East gas treatment agent: Depending on the tower will be used different types of substances such as activated carbon, alkaline solution, water, ...

All systems are manufactured by the most advanced and modern technologies in the world. Bringing solid products, durable, high performance, good quality.

* Methods and operating principles of the system

TH Vinasun offers many options for emissions treatment systems. Depending on the source of emissions and gases to be treated, we will provide different methods and equipment. However, it can be divided into 3 main methods:

1. Wet filter tower

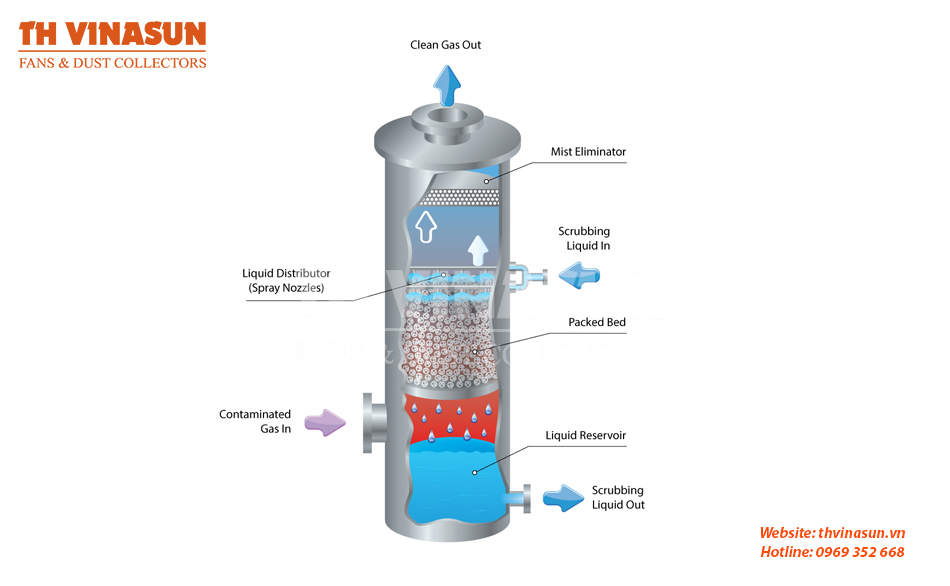

Wet filter tower includes a circular or rectangular cylindrical structure. The inside contains a cushion with an empty material and during operation is irrigated the solution. The usual empty material layer is different types of shapes the purpose of increasing the area of contact with gas, the material is usually colored metal, porcelain and plastic. The solution used can use water, alkaline or basic.

Wet filter tower

Principle of operation: The gas goes from the bottom to the empty material layer, when exposed to the wet surface of the empty layer of the polluting component in the form of a solid will be retained and the clean gas is released. The solid sediment is swept away by the solution and is periodically discharged in the form of mud. The material layer will be washed periodically to combat the phenomenon of obstruction of the air flow.

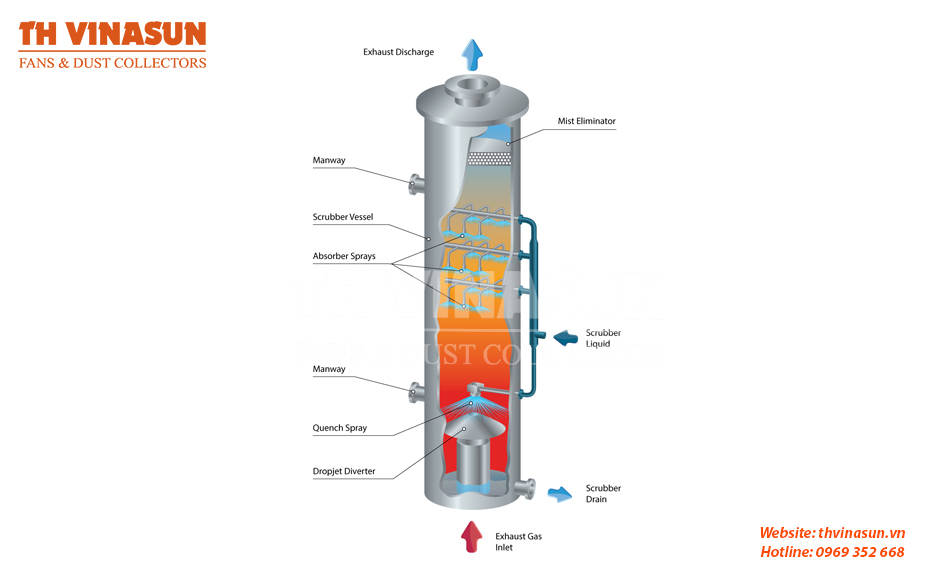

2. Air wash tower

To reduce operating costs, you can design a dense irrigation/ misting system instead of a high cross -sectional absorption layer in the wet filter tower. The dirty air stream when passing through the dense solvent dew will react chemically with the solvent, neutralized and escaped by discharge. Clean air goes back and escapes to the environment.

Air wash tower

Although the efficiency is not as high as the wet filter tower, the advantage of this design is high durability, simple design and operating costs are minimized, suitable for conditions in Vietnam.

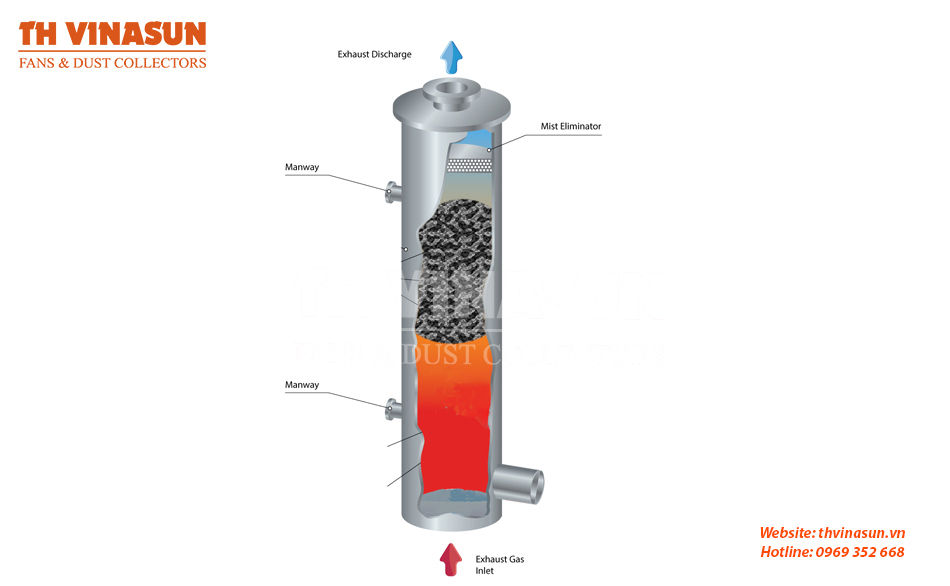

3. Adsorption tower

Adsorption is the process of gas separation based on the absorption of some absorption substances to pollutants in emissions. As in this process, polluting gas molecules in emissions are kept on the surface of the absorption material. The adsorbented material used is activated carbon.

Handling emissions by activated carbon

The adsorption process is also widely used for dehumidification in the air or in general gas environment, toxic dehydration and odor in emissions, recovering steam, valuable gas mixed in air or in emissions.

* Advantages of emissions treatment system

The exhaust treatment system produced by TH Vinasun has outstanding advantages such as:

- Module design system, very highly customized.

- Simple, easy -to -use ingredients.

- Easy to operate, warranty, maintenance.

- Low investment and operation costs.

- The durability of the system is high, suitable for harsh environments.

emissions treatment system

* Application of emissions treatment system

The emission treatment system due to many advantages should be applied in many different fields of industry such as:

- Treatment of emissions in factories and factories producing cement, stone, wood, metal and rubber.

- Treatment of emissions in brick kilns, boilers, paint rooms, laboratories.

- Treatment of emissions in electronic plants, welding factories, ....

Contact information vinasun

The exhaust treatment system of TH Vinasun always ensures the quality and the highest efficiency. Can meet all the strict customer requirements. Therefore, if your project is interested, please contact Th Vinasun at hotline 0969 352 668 for advice and quotation support.